diy injection molding 3d print

Injection molding machines are able to form very detailed plastic parts simply by squirting plastic into a mold. 3D printed injection molds are a time and cost-effective alternative for low-volume production.

Turn Your 3d Printer Into An Injection Molder Make

Full kits it include all the parts for the scanner.

. 3D printing can become a tool in DIY plastic molding. Customized Mold Manufacturing Service Plastic Injection Moulding Quick Details. Tried the same thing over a year ago as well but made a stupid mistake and th.

Plastic 3D printed molds are less stable than metal molds when subjected to the high temperature and pressure the injection molding process is known for. The idea behind 3d printing is to make hard tools. With our technology we open up the design space for glass.

Its now possible to. The time it takes to 3d print a mold depends on the size and complexity of the mold. The mould pattern was 3D.

Httpwwwschoneschienl Buster Beagle 3D instruction. The ring mould and sprue were all modelled in Solidworks and exported as STL files for 3D. The use of high-temperature resins has a high-temperature control.

DIY Injection Molding Step 1. They are also less expensive than CNC machining. Testing resin 3D printed molds on a DIY hand made injection molder at Pluspunt.

Also follow me on Instagram where I share the most. They also enable a more agile manufacturing. Easy to assemble and use.

3D printers squirt plastic. A 3D printed part can be completed in as little as 30 minutes to as much as 7 days. Injection molding of Glassomer materials on regular polymer injection molding machinery the easy way to shaping glass parts.

Now that desktop 3D printing has become widespread theres another production method crossing over into the DIY realm. This article will guide you through the whole. A 3D printing material that can survive the heat and pressure applied to the mold during injection molding.

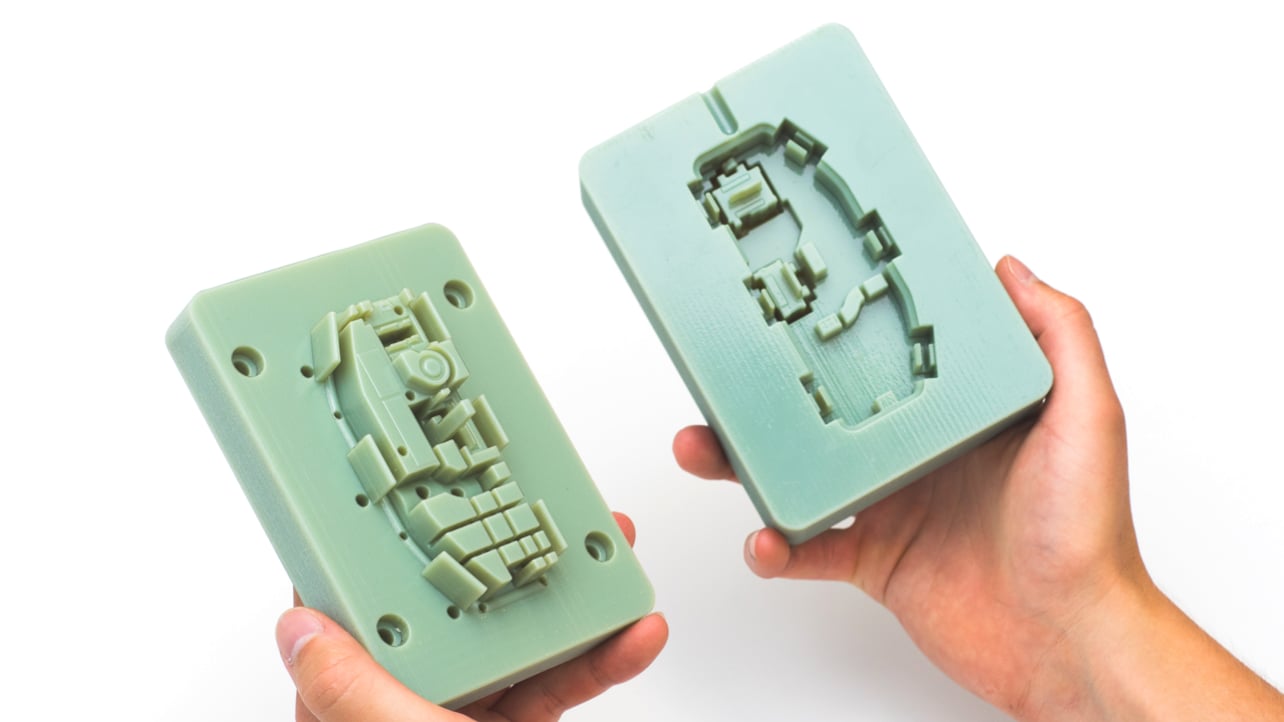

For prototyping and low-volume production approximately 10-1000 parts 3D printed injection molds provide a time- and cost-efficient solution. Product CNC Machining parts Color According customer needs Size According customer needs Mould base. A benchtop injection molder such as the Galomb Model-B100 or the.

Totally open source 3D scanner for 3D printing free to get the software.

3d Printed Molds For Injection Molding Hackaday

How Can I Use 3d Printing For Injection Molding Simple Guide

Diy All Electric Plastic Injection Molding Machine 3d Cad Model Library Grabcad

Injection Molding With 3d Printing How Its Used Youtube

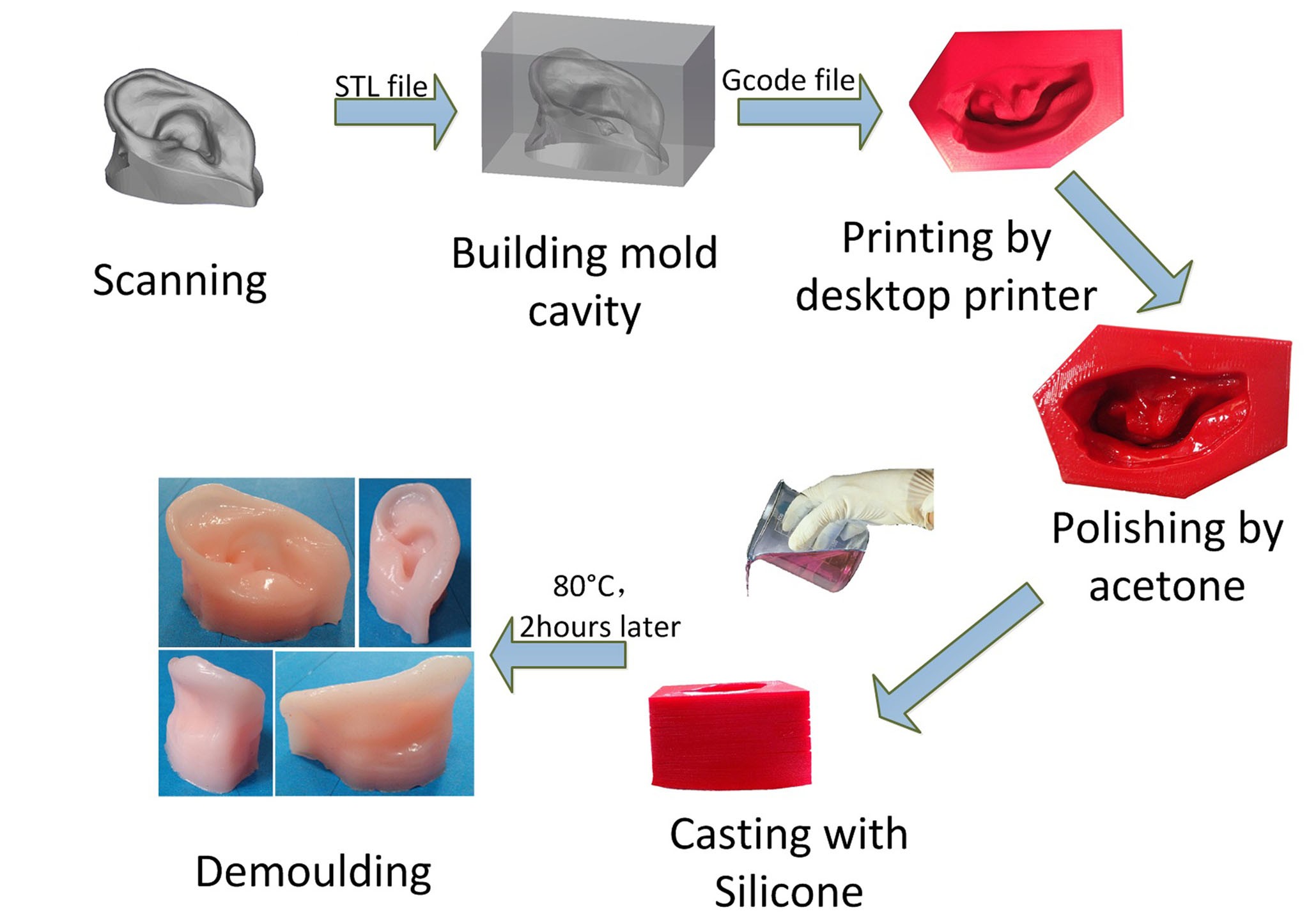

Fabrication Of Low Cost Soft Tissue Prostheses With The Desktop 3d Printer Scientific Reports

Watertight 3d Printing Part 2 Airtight Closable Models Original Prusa 3d Printers

Slideshow Watch Out Hobbyist 3d Printing A Here Comes Diy Inj Designnews Com

Make Your Own Injection Molding Machine Make

3d Printed Molds How To Get Started All3dp

Build Your Own Desktop Injection Molding Machine Youtube

Is It Possible To Recycle Abs Plastic For A Home 3d Printer Quora

Diy Injection Molding With 3d Printed Molds And How To Avoid Warping Fabbaloo

A Plastic Injection Machine You Can Use At Home Hackaday

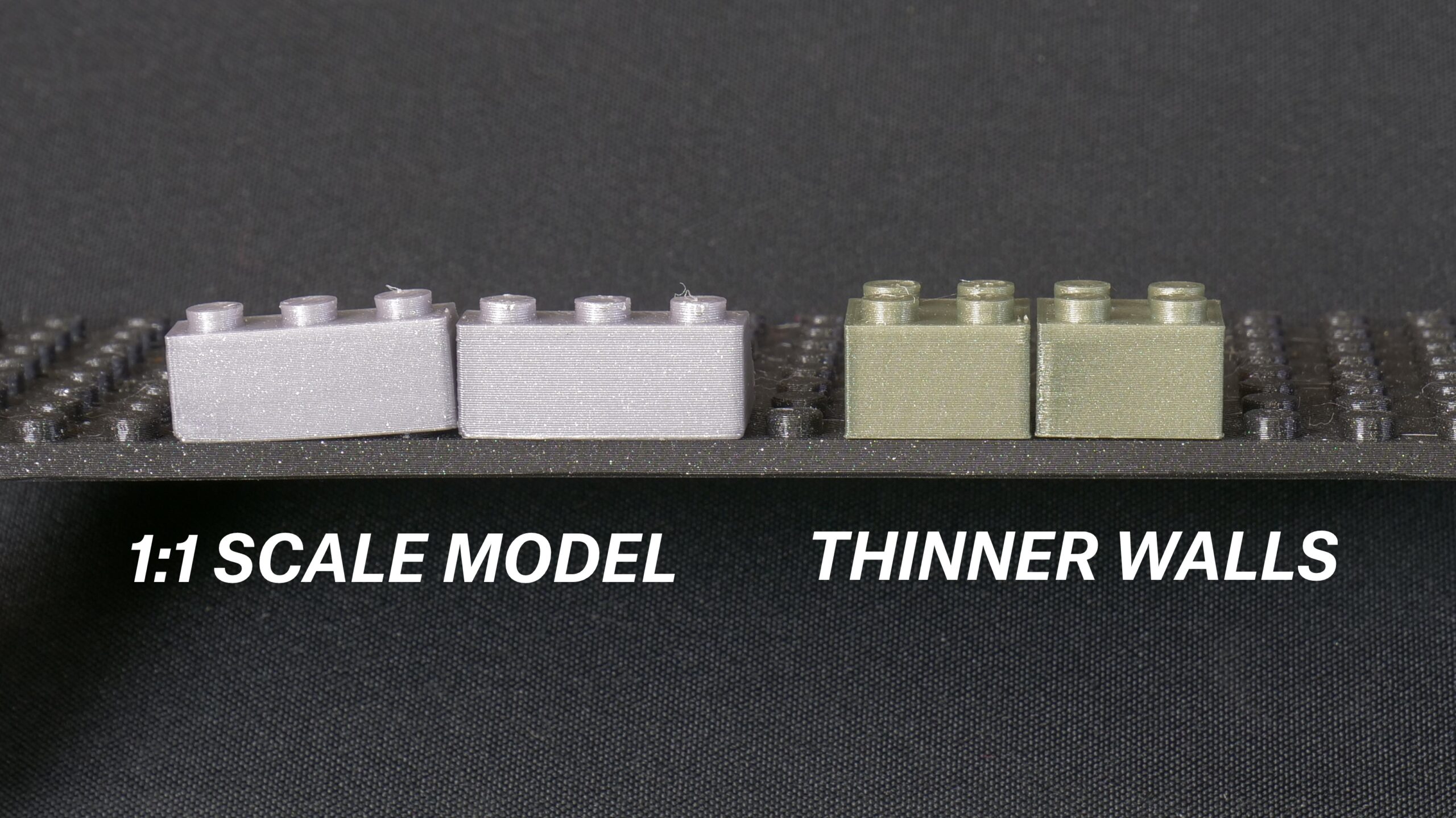

How To Make 3d Printed Lego And Lego Duplo Parts Original Prusa 3d Printers

How To Use 3d Printing For Injection Molding

Consumer Goods Unilever Iterates Faster With 3d Printing Stratasys

Basics Of Injection Molding Design 3d Systems

Injection Molds From Your 3d Printer Hackaday

Moving From 3d Printing To Injection Molding 5 Things To Consider 3dprint Com The Voice Of 3d Printing Additive Manufacturing